When our team reviews supplier quotes daily, we see the same pattern repeat China sourcing agent 1. Buyers lose thousands to fees they never knew existed. The frustration builds when your landed cost 2 exceeds budget by 30%.

To spot hidden fees in a China sourcing agent quote, demand itemized cost breakdowns covering product price, agent commission, shipping, and handling. Compare quotes against market benchmarks. Verify factory-direct pricing. Watch for exchange rate markups, inflated logistics costs, and vague service charges that signal potential kickbacks.

Let me walk you through the exact methods we use to audit quotes and protect our clients from costly surprises.

How can I tell if my sourcing agent is taking secret kickbacks from the factory?

Our experience coordinating between factories and overseas buyers has taught us one painful truth. Kickbacks remain the industry's worst-kept secret. You pay more, and someone else profits behind your back.

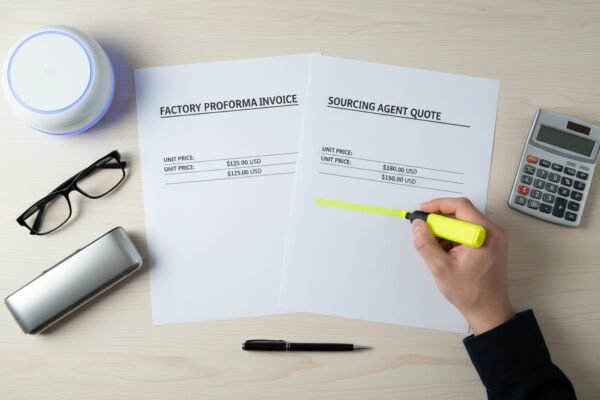

Detect kickbacks by requesting the factory's Proforma Invoice directly, comparing it against your agent's quote. A gap of 10-30% suggests hidden commissions. Also watch for agents who refuse factory contact details, block direct payments, or offer suspiciously low service fees below 3%.

The Kickback Mechanism Explained

Here is how kickbacks work. Your agent negotiates with the factory. The factory quotes $10 per unit. Your agent tells you $13 per unit. The extra $3 goes back to the agent as a "commission" from the factory. You never see the real price.

This practice inflates your costs by 10-30% on average. On a $100,000 order, that means $10,000 to $30,000 in hidden charges. Worse, this inflated invoice becomes the basis for import duties 3. A 25% tariff on $130,000 costs you $32,500 instead of $25,000.

Warning Signs Your Agent Takes Kickbacks

| Red Flag | What It Means | Risk Level |

|---|---|---|

| Commission under 3% | Too low to sustain business; profit comes elsewhere | High |

| Refuses factory contact info | Prevents price verification | High |

| Blocks direct factory payments | Needs money to flow through them | High |

| Vague service agreements | Hides actual cost structure | Medium |

| Higher quotes than competitors without explanation | Markup built into price | Medium |

| Delayed responses on basic questions | Avoiding transparency | Medium |

How to Verify Factory Pricing

Request a Proforma Invoice 4 directly from the factory. Do this before your agent gets involved. Compare the two numbers. Any difference above 5% deserves explanation.

Use third-party audits. Hire an independent inspector to visit the factory and confirm pricing. This costs $200-400 but saves thousands.

We always encourage our clients to make factory visits. Meet the supplier face-to-face. Ask direct questions about pricing and agent relationships. Most factories will be honest when asked directly.

The Real Cost of Kickback Agents

One case study shows the damage clearly. A buyer placed a $1 million order through a "free" sourcing agent. The agent inflated prices by 35% and took an additional 10-15% kickback from the factory. The buyer paid $620,000 more than necessary after tariffs were calculated on the inflated invoice. The factory received only $600,000.

Transparent agents charge 5-10% commission openly. They help you audit factory prices. They show you competing quotes. They align their success with your savings.

What red flags should I look for in the logistics and warehousing costs of my quote?

When we coordinate shipments from our Shenzhen warehouse, we see how easily logistics costs get inflated. Small markups on freight multiply across large orders. The numbers add up fast.

Red flags in logistics costs include vague "handling fees," inflated inland shipping rates exceeding $0.50/kg, warehousing charges without clear duration terms, and exchange rate markups above 2%. Always request itemized shipping quotes with carrier names, exact weights, and CBM calculations.

Common Logistics Fee Manipulations

Agents inflate logistics in several ways. They add handling fees without specifying what gets handled. They mark up inland trucking costs. They charge warehouse rent by the day when weekly rates exist.

The most common trick involves exchange rates 5. Your agent converts USD to RMB at rates 2-3% worse than market. On a $50,000 shipment, that hidden fee costs $1,000-1,500.

Logistics Cost Breakdown Template

| Cost Component | Acceptable Range | Red Flag Threshold |

|---|---|---|

| Inland trucking (per kg) | $0.15-0.35 | Above $0.50 |

| Warehouse rent (per CBM/week) | $3-8 | Above $15 |

| Handling/loading fees | $50-150 per container | Above $300 |

| Documentation fees | $25-75 | Above $150 |

| Exchange rate markup | 0.5-1% | Above 2% |

| FOB coordination fee | $100-300 | Above $500 |

Questions to Ask About Shipping Costs

Ask your agent these specific questions:

Which freight forwarder 6 handles my shipment? Get the company name. Call them directly. Verify the quoted rate.

What is the exact weight and CBM of my order? Calculate yourself. Compare against the quote. Small "adjustments" in weight add up.

What exchange rate will you use? Request the date and source. Compare against XE.com or Google Finance.

Are warehouse costs included in the quote? How many free days do I get? What happens after?

Warehousing Tricks to Watch

Some agents charge warehousing from the moment goods arrive at their facility. Others provide 7-14 free days. This difference matters for larger orders requiring consolidation.

Watch for "storage fees" that appear after shipment. Your agent may claim customs delays required extended storage. Always establish warehousing terms in writing before production begins.

Our clients receive detailed warehouse logs showing arrival dates, departure dates, and exact storage durations. This transparency eliminates disputes.

Are there hidden service fees buried in my product's unit price?

Our production management team has seen quotes structured in countless ways. Some agents list every fee separately. Others bundle everything into the unit price. The second approach often hides surprises.

Hidden service fees commonly buried in unit prices include quality inspection costs, sampling charges ($50-300), packaging upgrades, labeling, and domestic handling. Request detailed breakdowns separating material costs, labor, overhead, and agent services to expose these embedded charges.

The Unit Price Deception

A quote showing $5.00 per unit looks simple. But what does it include?

Some agents negotiate $4.00 with the factory. They add their 10% commission ($0.40). Then they include inspection ($0.20), packaging ($0.25), and handling ($0.15). The total reaches $5.00. But you never see this breakdown.

Other agents show $4.40 per unit plus separate service fees. This transparency lets you compare factory prices and negotiate each component.

Services Often Hidden in Unit Prices

| Hidden Service | Typical Cost | How to Detect |

|---|---|---|

| Pre-shipment inspection | $0.05-0.20/unit | Ask if inspection is included |

| Product sampling | $50-300 per design | Request sample cost separately |

| Custom packaging | $0.10-0.50/unit | Compare against standard packaging quotes |

| Labeling/barcoding | $0.02-0.10/unit | Specify labeling requirements upfront |

| Domestic handling | $0.05-0.15/unit | Ask what "handling" means specifically |

| Photography/documentation | $100-500 per order | Clarify if marketing assets are included |

How to Unbundle Unit Prices

Ask your agent to provide a cost breakdown showing:

- Raw material cost per unit

- Labor cost per unit

- Factory overhead per unit

- Factory profit margin

- Agent commission

- Quality control 7 costs

- Packaging costs

- Any other fees

If your agent cannot provide this breakdown, they may not know the real factory price. Or they may be hiding their markup.

Comparing Agent Fee Structures

| Fee Model | Typical Rate | Pros | Cons |

|---|---|---|---|

| Commission-based | 5-10% of order value | Aligns agent incentive with order size | Can discourage cost negotiations |

| Flat fee per project | $500-1,000 | Predictable cost | May not cover complex orders |

| Monthly retainer | $300-1,000 | Ongoing support | Commits you regardless of volume |

| "Free" service | 0% visible | Low upfront cost | Hidden kickbacks inflate prices |

| Hybrid (commission + flat) | 3-5% + $300-500 | Balances incentives | More complex accounting |

We use a transparent commission model. Our clients see exactly what the factory charges. They see exactly what we charge. No confusion. No surprises.

How do I ensure my quote includes all quality inspection and compliance testing costs?

When we manage production for our clients, quality control becomes the difference between profit and disaster. Skipped inspections lead to defective products. Defective products lead to returns, refunds, and damaged reputations.

Ensure quotes include inspection costs by explicitly requesting line items for pre-production samples, in-line inspections, pre-shipment inspections, and third-party lab testing for compliance. Ask which standards apply (CE, FCC, UL) and whether certification fees are included. Budget $200-500 per inspection.

Types of Quality Control Costs

Quality control involves multiple checkpoints. Each costs money. Each should appear in your quote.

Pre-production inspection verifies raw materials and components before manufacturing begins. This catches problems early. Cost: $150-300 per visit.

In-line inspection happens during production. Inspectors check processes and catch defects before completion. Cost: $200-400 per visit.

Pre-shipment inspection examines finished goods before they leave the factory. This is your last chance to reject defective products. Cost: $200-500 per visit.

Compliance Testing Requirements

Different markets require different certifications. Each certification requires testing. Each test costs money.

| Market | Common Certifications | Typical Testing Cost | Timeline |

|---|---|---|---|

| United States | FCC, UL, FDA | $1,000-5,000 | 2-6 weeks |

| European Union | CE, RoHS | $500-3,000 | 2-4 weeks |

| Australia | SAA, RCM | $800-2,500 | 2-5 weeks |

| Canada | CSA, IC | $1,000-4,000 | 3-6 weeks |

Questions to Ask About Inspections

Ask your agent these questions before confirming your order:

Does the quote include pre-shipment inspection? How many units will be inspected? What sampling method (AQL level) will be used?

Who performs the inspection? Is it your agent's team or a third-party company like SGS, Bureau Veritas, or Intertek?

What compliance certifications does my product need for my target market? Are testing costs included? Which lab will perform the testing?

What happens if inspection finds defects? Who pays for re-inspection?

Building Inspection Costs Into Your Budget

Many buyers receive quotes without inspection costs. They assume everything is included. Then they face unexpected charges of $500-2,000 before shipment.

We include inspection planning in every project. Our clients know upfront what inspections will occur, when they will happen, and what they will cost.

For complex electronics, budget 2-5% of order value for quality control. For simple products, budget 1-2%. These costs protect you from much larger losses due to defects.

The Cost of Skipping Inspections

One client we worked with inherited a previous agent's mess. The agent charged no inspection fees because no inspections happened. The shipment arrived with 15% defective units. Returns and replacements cost three times what inspections would have cost.

Quality control is not optional. It is essential. Make sure your quote reflects this reality.

Conclusion

Hidden fees turn profitable imports into costly mistakes. Demand itemized breakdowns. Verify factory pricing directly. Question every vague charge. The extra effort protects your margins and builds supplier relationships based on transparency.

Footnotes

- Explains the role and function of a sourcing agent. ↩︎

- Defines landed cost and its components for international trade. ↩︎

- Provides a comprehensive explanation of tariffs and import duties. ↩︎

- Explains what a Proforma Invoice is and its purpose in trade. ↩︎

- Explains what exchange rates are and their significance in international transactions. ↩︎

- Defines the role and responsibilities of a freight forwarder. ↩︎

- Simplilearn provides a detailed definition and explanation of quality control. ↩︎

- Sprinto offers a comprehensive guide to compliance testing, including its definition and importance. ↩︎